ISO Surface Parameter Symbols. A good design drawing can indicate all the details needed to produce a mechanical CNC milling part in an easy way.

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Graphically Ra is the area between the roughness profile and its centerline divided by the evaluation length.

. See the Below table to understand the representation of Surface Finish on Engineering Drawings. Our chart of surface finishes by manufacturing process see above gives both. It is the average roughness in the area between the roughness profile and its mean line.

Surface Finish Units From RA To RZ. The BIS recommended symbols for indicating the surface finish are shown in Table A. Based on roughness deviations.

Optional Select a symbol preset and modify as needed. You might have seen the symbols like Ra 08 or Ra 25 or N9 on various features of component. Plated milled cold drawn.

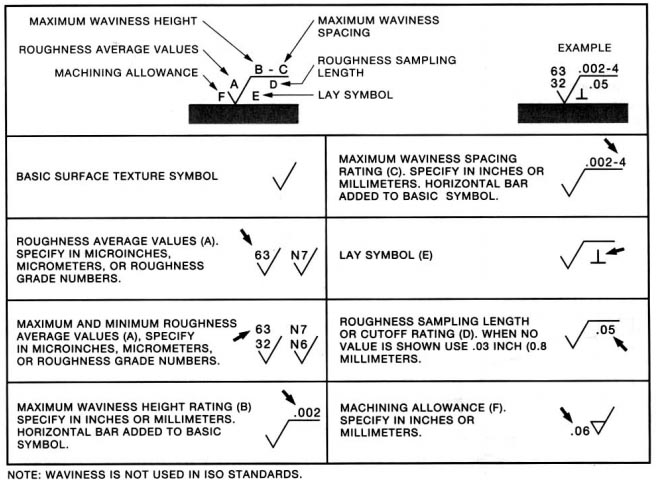

Maximum waviness spacing roughness sampling length e lay symbol maximum waviness spacing rating c. Surface Roughness Significance and symbol interpretation in drawing It has been very much common practice to indicate surface roughness symbols in the drawing. Surface finish symbols are formed by combining the Symbol and Lay Direction direction of lay.

Set the attributes and values for the symbol in the Surface Texture dialog box and click OK. Example 63 32 002-4 05 002-4 05 06 60 63 002 lay symbol e roughness sampling length or cutoff rating d. The root symbol can also be placed on a dimension lead line as long as it stays readable.

It is suggested to indicate the surface roughness on drawing by symbols. Ra and D are two important surface finish parameters The Surface Finish Units we would use for parameters like Ra would be either micro-inches English or Imperial or micrometers Metric. Surface roughness symbol is given to convey manufacturing process related information only.

Ra is average roughness and its under-estimates surface height variations. These symbols are given irrespective of material and its surface condition. When we try to measure a surface finish the methods fall into three categories.

Use these geometric dimensioning and tolerancing GDT shapes to create annotated mechanical drawings. Ra Rz in most cases. Other options are available and in particular simplified writing.

Position on a drawing. Rp max height profile Rv max profile valley depth Rz max height of the profile Rc mean height of profile Rt total height of the profile Ra arithmetic mean deviation of the profile Rq root mean square deviation of the profile Rsk skewness of the profile Rku kurtosis of the profile RSm mean width of the profile. This section will explain how to write these symbols to indicate surface textures.

Specify in inches or millimeters. The methodology to do this is described in ISO 13022001. Surface Finish consists of waviness lay and roughness but it is common for only roughness to be specified on technical drawings.

Symbols that indicate the surface texture of machined and structural parts are used in industrial diagrams. You can find the list of common engineering drawing abbreviations. For roughness value less than 25μm the equilateral triangular symbol is used.

When no value is shown use 03 inch 08 millimeters. Surface finish a subjective term. The surface finish symbols used in engineering drawings are defined by technical standards such as ISO ANSI or AS Australian standard.

Section 631 above described parameters using lTnN However no information was given concerning how these are added to features on a drawing. The pictorial representation using these symbols is defined in ISO 13022002. The mean of the squared deviation over the.

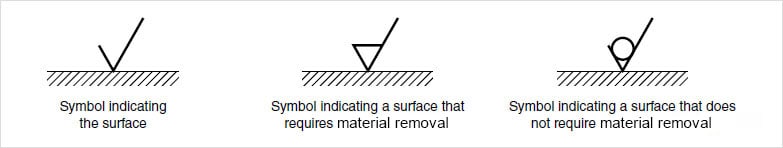

And how we will represent these in the Engineering Drawings. The symbol may be connected to the surface by a leader line terminating in an arrow. The surface roughness is generally indicated with the symbol and displays information including surface roughness value cutoff value machining method sampling length surface waviness and crease direction symbol as below.

Geometric dimensioning and tolerancing GDT is a system for. Surface Roughness symbol in drawing. Rz is mean roughness depth and it approximates the size of the most severe surface height variations.

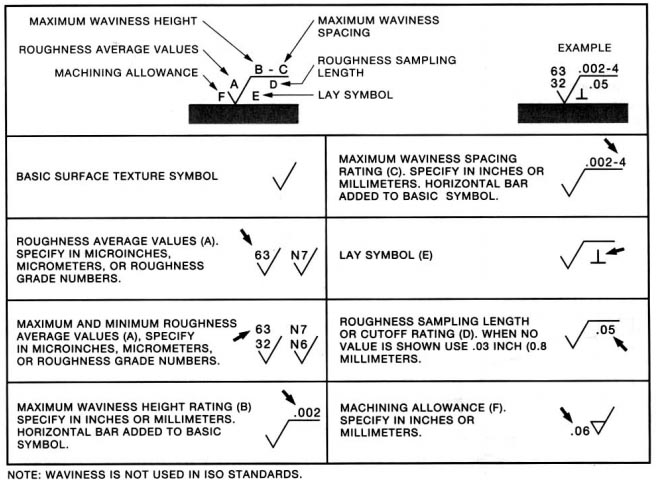

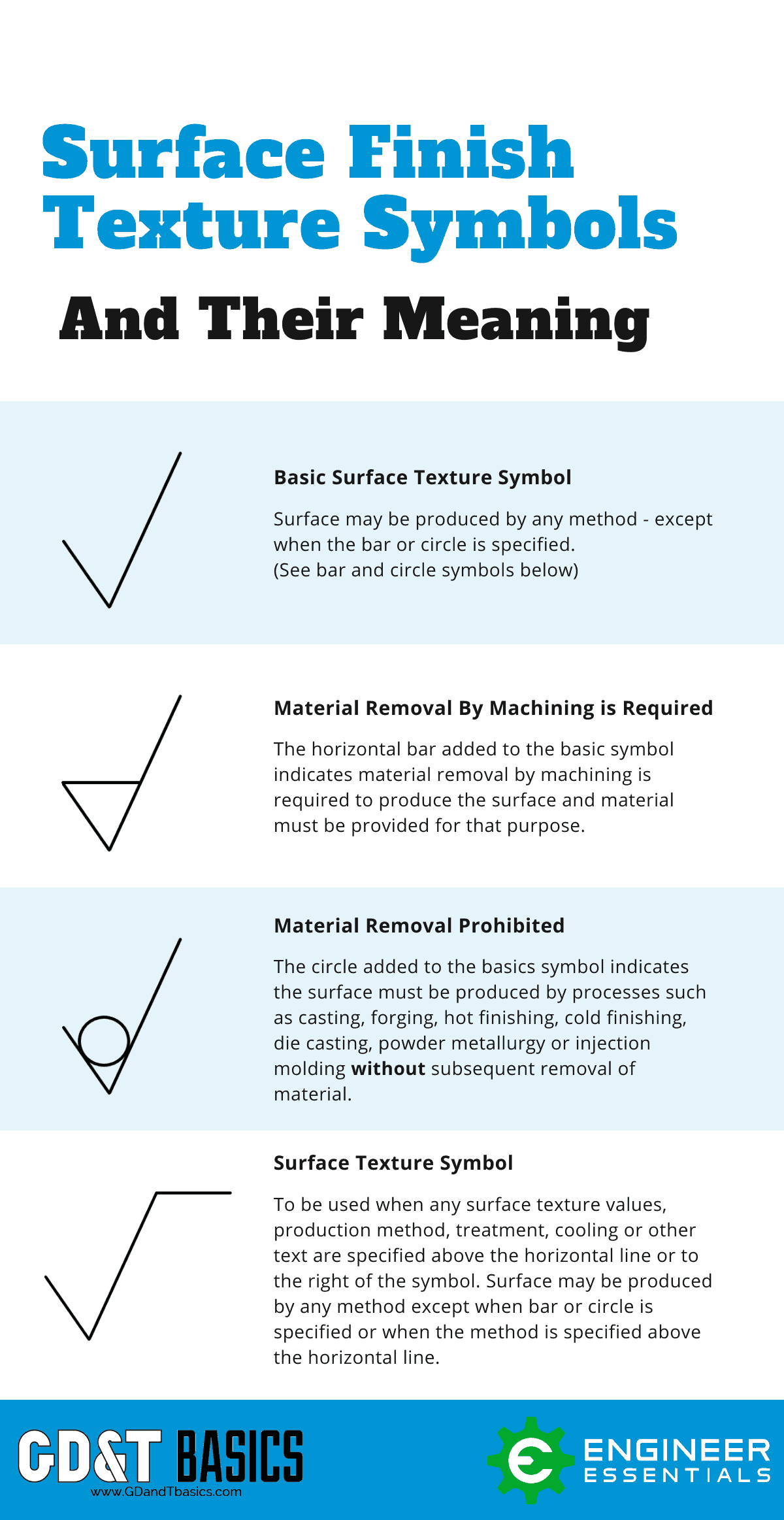

There are three surface roughness symbols see figure below indicating the surface a required material removal b. The vector stencils library Dimensioning and tolerancing contains 45 symbols of geometric dimensions and mechanical tolerances geometric symbols callouts and text boxes and inserts. We should not confuse the Surface Finish with the Surface Roughness.

The functions can be used individually to control just that element of the SF Symbol or вЂ. For ISO and related drafting standards you can display surface finish symbols per 2002 standards by selecting Display symbols per 2002 in Document Properties Surface Finishes. INDICATION OF ROUGHNESS SYMBOLS ON DRAWING.

Roughness value in micrometers preceded by parameter symbol. Ra is also known as Arithmetic Average AA or Center Line Average CLA. Root-mean-square RMS the square root of.

Method of indicating surface finish and texture. Arithmetic Average AA Ra arithmetic mean value of roughness. To place the symbol do one of the following.

Drawing Rules Annotation Surface Finish Symbol A surface finish symbol rule consists of separate functions to control individual elements of the surface finish symbol. For roughness value less than 25μm the equilateral triangular symbol is used. Surface Finish Representation Surface Finish Symbols Chart Source.

Requirements for surface finish are frequently found on technical drawings for mechanical parts particularly where parts fit together tightly move against each other or form a seal. Indication of Surface Roughness by Symbols. Because there is no large space on a drawing to contain all the text to illustrate the image abbreviations and symbols are often used in engineering drawings to communicate the characteristics of the product to be manufactured.

Understanding surface roughness symbols. It is the average roughness in the area between the roughness profile and its mean line. The symbol or the arrow should point from outside the material of the piece either to the line representing the surface or to an extension of it as shown in Figure a 20.

For the roughness values greater than 25μm the symbol is used. On the ribbon click Annotate tab Symbols panel Surface. As Dimension controls the shape and size of the feature surface roughness symbol goes one level below and controls.

Y the vertical deviation from nominal surface. The root symbol is placed on a drawing with the tip of the triangle in contact with the surface including on vertical faces it has to be rotated to the left then. Unless written specifically on the symbol they do not carry the surface texture type ie.

It is based on what is termed a tick symbol that defines the SF and points to the surface in. You can select the face in a part assembly or drawing document. Horizontal bar added to basic symbol.

The American Society of Mechanical Engineers ASME has published the Y1436M Surface Texture Symbols standard which illustrates the proper specification and use of surface. It is suggested to indicate the surface roughness on drawing by symbols.

Understanding Surface Roughness Symbols Introduction To Roughness Keyence America

Surface Finish Surface Roughness It S Indications Symbols

Surface Roughness Symbol In Drawings Mechanical Engineering General Discussion Eng Tips

Surface Roughness Indication Symbols Surface Roughness Symbol Indication In Hindi Youtube

The Basics Of Surface Finish Gd T Basics

Solved Iso Surface Roughness Symbol Missing Roughness Autodesk Community Fusion 360

Surface Finish Texture Symbols Drafting Gd T Simpliengineering

0 comments

Post a Comment